Over the years Factory Automation has been tasked to solve some of the industries toughest challenges. This is where we shine. With over 125 years of combined experience, we’ve seen a lot and have a lot to offer. We’re a nimble, creative and diligent team. Let us show you.

Conveyors, Pallet Dispensers, Slip Sheet Hoppers & Case Openers

High Speed Case Opener

Engineered for precision and efficiency, our High Speed Case Opener quickly processes a wide variety of box sizes without compromising product integrity. Ideal for high-throughput environments, it reduces manual labor and increases operational speed.

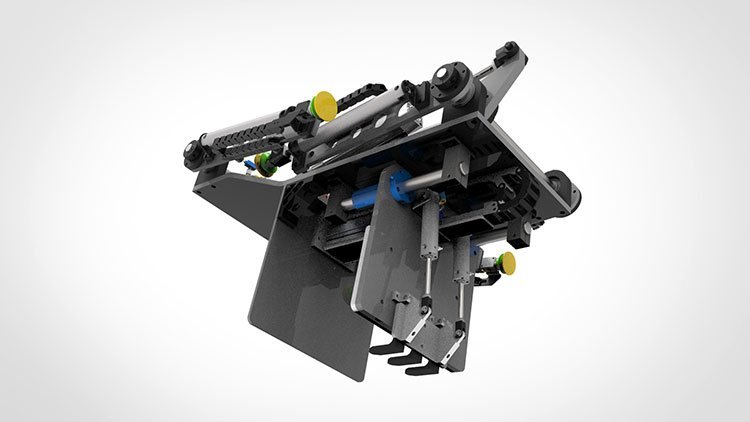

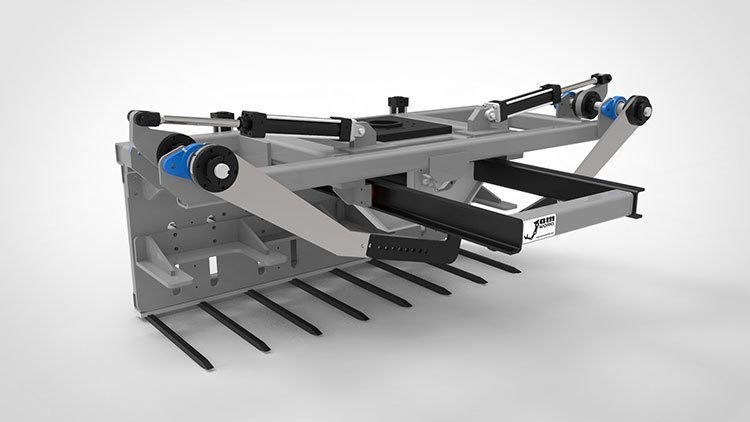

Industrial Pallet Stack and De-Stack

This automated system streamlines the handling of empty pallets by efficiently stacking and de-stacking with minimal operator involvement. Built for durability and smooth operation, it improves warehouse organization and reduces downtime in material flow processes.

Factory Automation Conveyors

Designed to optimize material transport, our conveyor systems integrate seamlessly with automated workflows. From assembly lines to packaging stations, they ensure consistent, reliable movement of products with customizable configurations for speed, size, and layout.

Robotic End of Arm Tooling

Heavy duty industrial bag gripper EOAT

Built for high-capacity handling, this end-of-arm tooling securely grips and lifts heavy or irregularly shaped bags with precision. Ideal for palletizing applications, it ensures reliable performance in demanding environments such as agriculture, chemicals, and bulk materials.

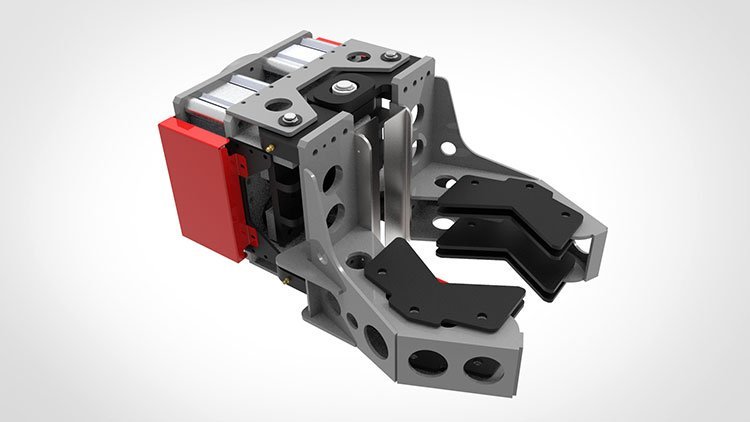

Heavy duty industrial clamp gripper EOAT

Engineered for strength and stability, this clamp-style end-of-arm tool handles rigid containers, crates, and large parts with secure, consistent pressure. Perfect for high-throughput operations, it supports automation in packaging, warehousing, and manufacturing lines.

Heavy duty industrial pallet gripper EOAT

Purpose-built for robotic palletizing and depalletizing, this gripper securely engages pallets and slip sheets with rugged, reliable performance. Ideal for high-volume logistics and warehousing, it enhances automation by reducing manual lifting and improving cycle times.

Heavy duty industrial fork gripper EOAT

Designed for precise lifting and placement, this fork-style end-of-arm tool handles bins, totes, and bulky products with ease. Its reinforced forks and controlled motion make it ideal for heavy-duty applications in distribution, manufacturing, and automated warehousing.

High Temp. Heavy duty foundry gripper EOAT

Engineered for extreme environments, this gripper withstands high heat and harsh conditions common in foundries and metalworking applications. Its robust construction and heat-resistant components ensure safe, reliable handling of castings, molds, and hot materials during automated transfer.

Robotic Packaged Cells

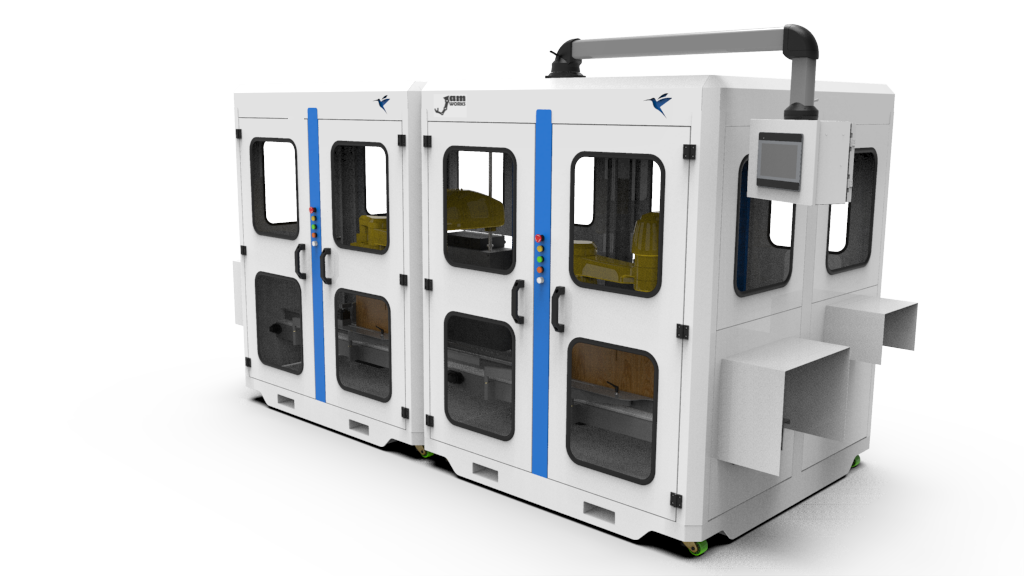

Hummingbird Case Packer

Compact, fast, and precise, the Hummingbird Case Packer is ideal for automated packing of lightweight or delicate products. Its modular design allows easy integration into existing lines, delivering consistent case loading with minimal footprint and rapid changeovers.

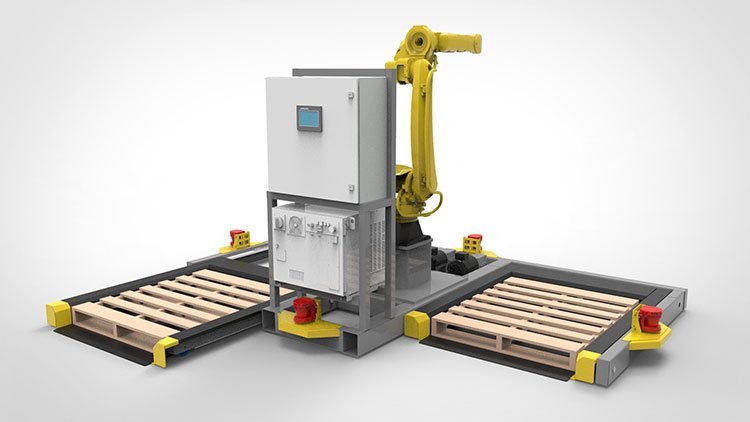

Co-Pak Pal portable palletizer

A flexible solution for end-of-line automation, the Co-Pak Pal delivers reliable palletizing in a compact, mobile format. Designed for quick deployment and easy relocation, it’s ideal for co-packing operations, seasonal lines, or facilities with limited space.

Fenceless Palletizing

Utilizing advanced safety-rated sensors and collaborative robot technology, fenceless palletizing eliminates the need for bulky guarding while maintaining operator safety. This space-saving solution enhances workflow flexibility and simplifies integration in tight or shared workspaces.

Shop setup of small palletizer

Designed for quick integration and minimal disruption, our small palletizer setup fits seamlessly into compact production environments. Preconfigured for efficiency, it’s ideal for low to mid-volume operations looking to automate stacking without overhauling existing workflows.

Industrial Spot Welding Cell

This fully automated cell delivers consistent, high-strength welds for sheet metal assemblies and structural components. Equipped with precision robotics and integrated safety systems, it ensures repeatable quality, reduced cycle times, and improved worker safety in demanding manufacturing environments.

Robots: .5 - 2300 KG Payload Range

Fanuc Industrial Robots

Known for reliability and performance, FANUC robots handle a wide range of automation tasks—from material handling and welding to packaging and assembly. With unmatched uptime and a broad payload range, they support scalable automation across virtually any industry.

Fanuc Collaborative Robots

FANUC collaborative robots (cobots) are designed to work safely alongside humans without the need for fencing. Easy to program and deploy, they offer precise, flexible automation for tasks like inspection, light assembly, packaging, and machine tending - ideal for dynamic production environments.

Fanuc Class 1 Div 1 Robots

Engineered for hazardous environments, FANUC’s Class 1 Div 1 robots are certified for use in areas with flammable gases, vapors, or dust. Built with explosion-proof housings and sealed components, they ensure safe, reliable automation in industries like oil and gas, chemical processing, and aerospace manufacturing.

Fanuc Delta (Spider) Robots

Designed for ultra-fast, high-precision pick-and-place operations, FANUC Delta (Spider) Robots excel in packaging, sorting, and small part handling. With lightning-fast cycle times and hygienic design options, they’re ideal for food, pharma, and electronics applications requiring clean, high-speed automation.

Automated Driverless fork lifts

These autonomous forklifts navigate complex warehouse environments without human intervention, using sensors, cameras, and mapping software to transport pallets with precision. Ideal for high-traffic or repetitive material handling tasks, they boost efficiency, reduce labor costs, and enhance workplace safety.

Fanuc Welding Robots

FANUC welding robots deliver consistent, high-quality welds across MIG, TIG, and spot welding applications. Engineered for precision and uptime, they integrate seamlessly with vision systems and positioners to support automated welding in automotive, fabrication, and heavy manufacturing environments.

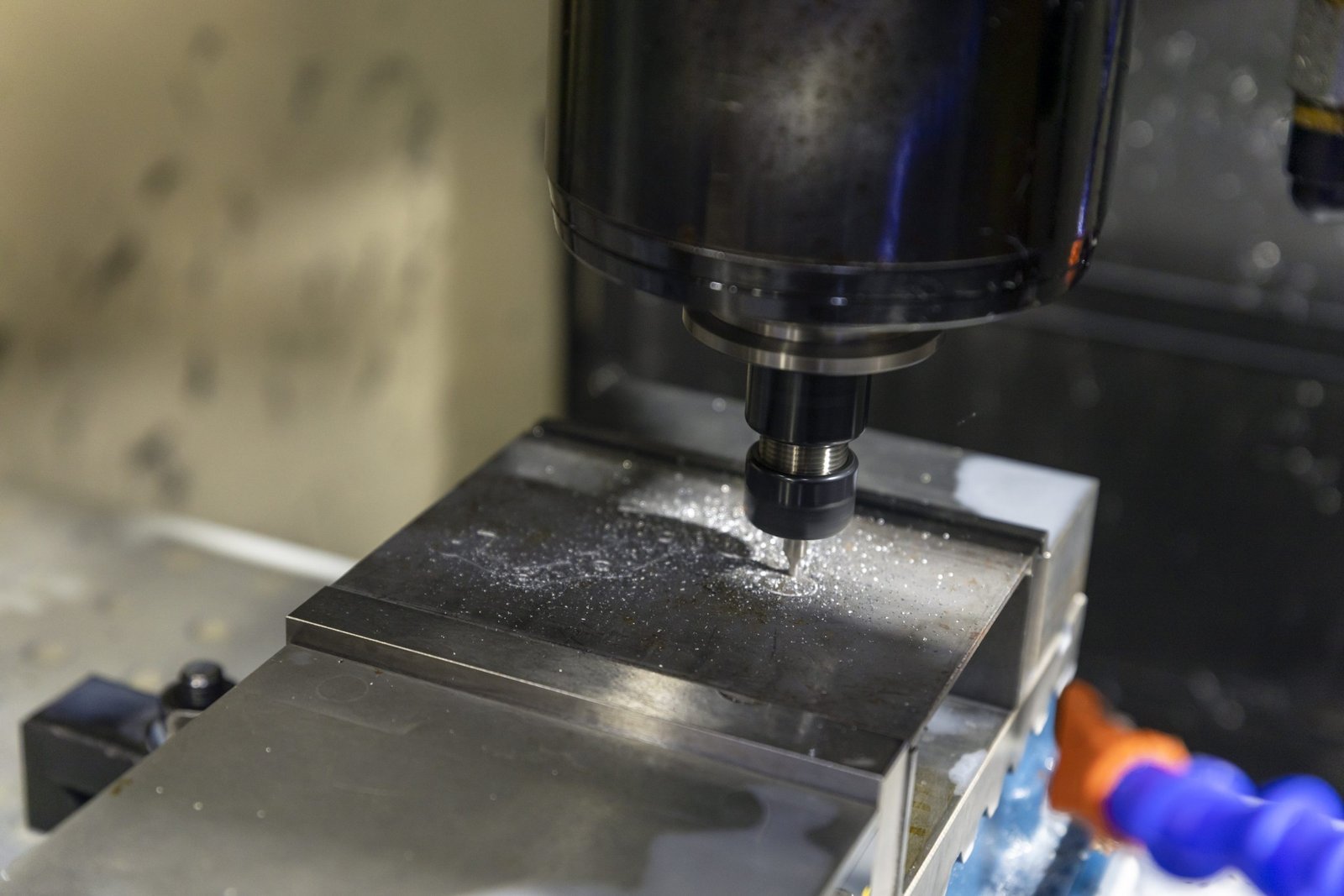

Custom Fabrications and Parts